Overload protection devices play a critical role in safeguarding your equipment. These devices prevent damage caused by excessive current, ensuring smooth operations and reducing costly downtime. Choosing the right device from the 过载保护系列, such as the BK1-10BN or BK1-10BL, ensures safety, efficiency, and compliance with industry standards. Proper selection protects your investment and enhances performance.

Key Takeaways

- Overload protection devices stop equipment from breaking due to too much current. They keep things safe and help avoid expensive delays.

- Pick the right overload protection device for your needs. Think about motor details and the environment where it will be used.

- Check and maintain overload protection devices often. Inspect them every three to six months to keep them working well.

What Are Overload Protection Devices?

Definition and Purpose

Overload protection devices are essential components in electrical systems. They monitor the flow of current and prevent damage caused by excessive electrical loads. When a circuit experiences more current than it can handle, these devices step in to stop the flow. This action protects your equipment from overheating, short circuits, and potential failure.

You rely on these devices to ensure the safety of your machinery and electrical systems. They also help you avoid costly repairs and downtime. Whether you are working with industrial motors, home appliances, or commercial equipment, overload protection devices are a critical safeguard. The 过载保护系列 offers a range of options designed to meet various needs, ensuring your system operates efficiently and safely.

How They Work to Protect Equipment

Overload protection devices operate by detecting abnormal current levels. When the current exceeds the safe limit, the device activates to interrupt the circuit. This interruption prevents overheating and damage to connected equipment.

Different types of devices achieve this in unique ways. For example, thermal overload relays use heat-sensitive components to detect excessive current. Magnetic relays rely on electromagnetic forces, while electronic relays use advanced sensors and microprocessors. The 过载保护系列 includes devices tailored to specific applications, giving you the flexibility to choose the right solution for your system.

By understanding how these devices work, you can make informed decisions about protecting your equipment. Proper selection and use of overload protection devices ensure long-term reliability and safety.

Types of Overload Protection Devices in the 过载保护系列

Thermal Overload Relays

Thermal overload relays use heat to detect excessive current. These devices contain a bimetallic strip that bends when it heats up due to high current. This bending action triggers the relay to disconnect the circuit. You can rely on thermal relays for applications where gradual temperature changes occur. They are ideal for protecting motors in the 过载保护系列, especially in environments with stable operating conditions.

Magnetic Overload Relays

Magnetic overload relays respond to sudden spikes in current. They use an electromagnetic coil to detect these surges. When the current exceeds the safe limit, the coil activates and interrupts the circuit. These relays work well in situations where quick response times are critical. If you need reliable protection for equipment prone to short bursts of high current, magnetic relays in the 过载保护系列 are a great choice.

Electronic Overload Relays

Electronic overload relays offer advanced protection by using sensors and microprocessors. These devices monitor current levels with precision and can provide additional features like diagnostics and remote monitoring. You should consider electronic relays for modern systems requiring high accuracy and flexibility. The 过载保护系列 includes electronic relays designed for complex applications.

Fuse-Based Overload Protection Devices

Fuses are simple yet effective devices for overload protection. They contain a metal wire that melts when the current exceeds a specific threshold, breaking the circuit. Fuses are cost-effective and easy to replace. However, they are single-use devices. If you prefer a straightforward solution for basic applications, fuse-based devices in the 过载保护系列 can meet your needs.

Circuit Breakers for Overload Protection

Circuit breakers combine the functionality of relays and fuses. They detect overloads and interrupt the circuit, but unlike fuses, they can be reset and reused. Circuit breakers in the 过载保护系列 offer durability and convenience. You can use them in a wide range of applications, from residential to industrial systems.

Tip: Always match the type of overload protection device to your specific application to ensure optimal performance and safety.

How to Select the Right Overload Protection Device

Assessing Motor Specifications

Start by understanding the motor’s specifications. Check the rated current, voltage, and horsepower. These details help you determine the type of overload protection device that matches your motor’s requirements. For example, a motor with high starting currents may need a magnetic overload relay. Always refer to the motor’s nameplate for accurate information.

Considering Environmental Conditions

Evaluate the environment where the device will operate. High temperatures, humidity, or dust can affect performance. Choose a device designed to withstand these conditions. For instance, thermal overload relays may not perform well in fluctuating temperatures. In such cases, electronic relays offer better reliability.

Understanding Compliance Standards

Ensure the device complies with industry standards and regulations. Look for certifications like UL, IEC, or NEMA. These certifications guarantee the device meets safety and performance requirements. Compliance also ensures your system adheres to legal and insurance guidelines.

Evaluating Application-Specific Needs

Consider the specific needs of your application. Industrial systems may require advanced features like remote monitoring or diagnostics. Simpler applications might only need basic protection. Match the device’s capabilities to your system’s complexity for optimal results.

Determining the Class and Rating of the Device

Select a device with the correct class and rating. The class defines the response time, while the rating indicates the maximum current it can handle. For instance, Class 10 devices trip faster than Class 20 devices. Choose a class and rating that align with your motor’s operating conditions.

Tip: Always consult the manufacturer’s guidelines to ensure proper selection and compatibility.

Installation and Configuration Best Practices

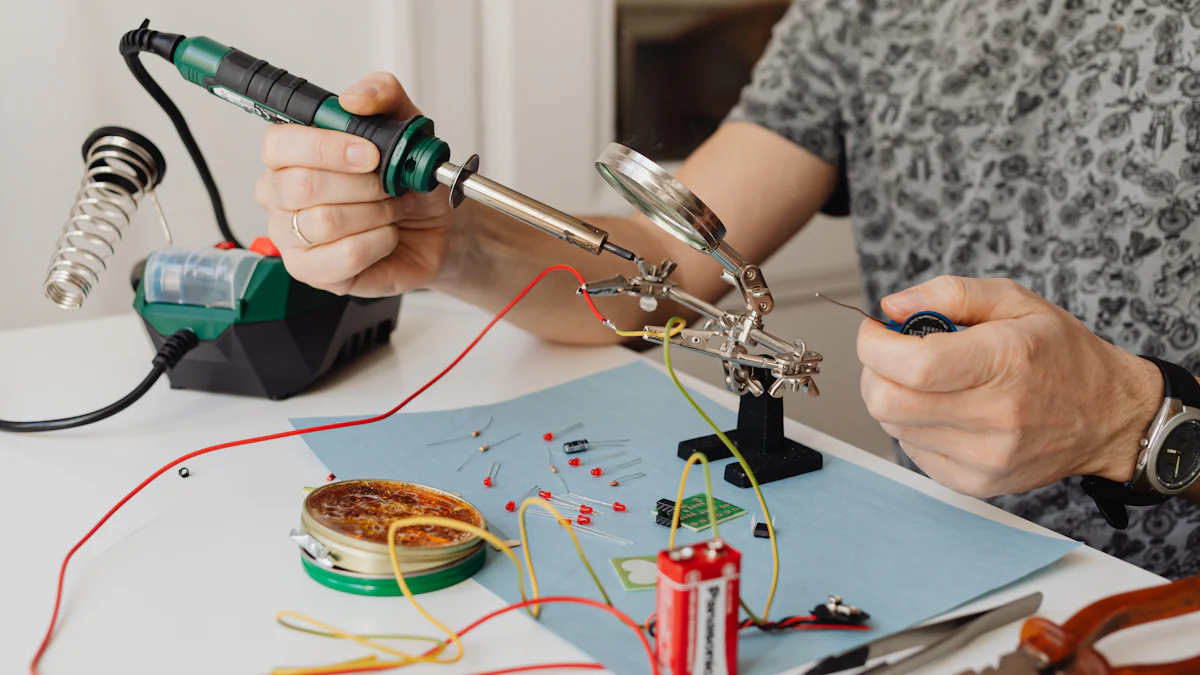

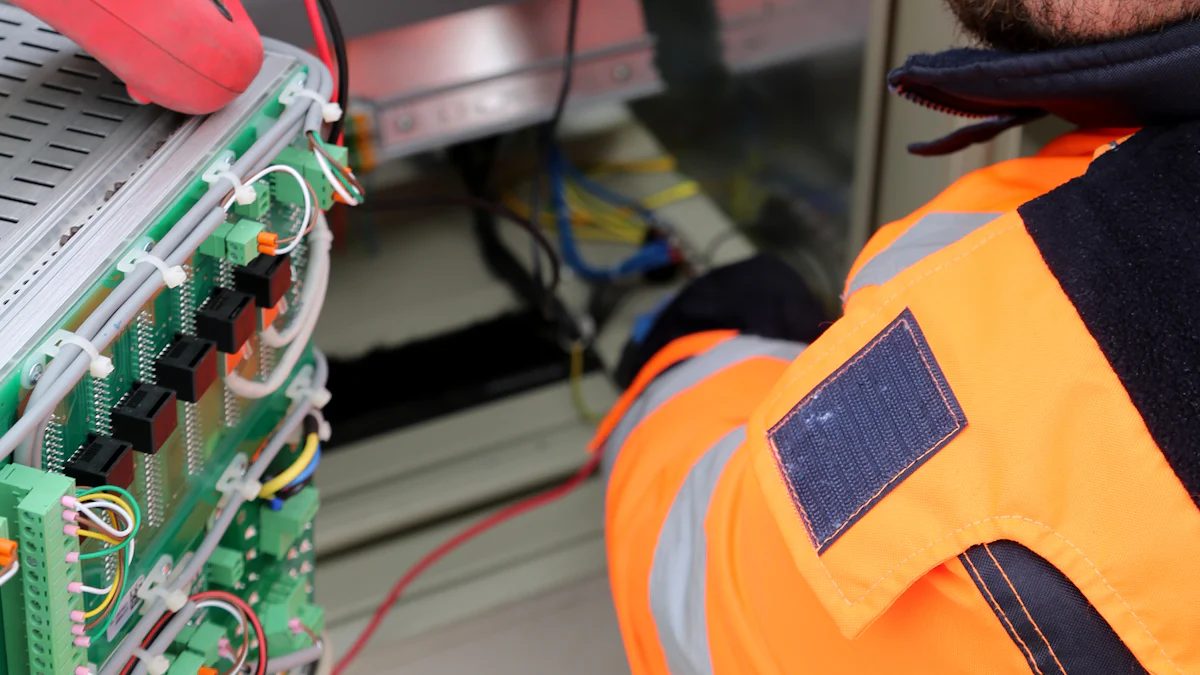

Proper Placement and Mounting

You should always place overload protection devices in a location that ensures easy access for maintenance and inspection. Mount the device securely on a stable surface to prevent vibrations or movement during operation. Use the manufacturer’s recommended mounting brackets or enclosures to ensure proper alignment and protection.

Avoid placing the device near heat sources or in areas with excessive moisture or dust. These conditions can reduce its lifespan and reliability. If the environment is harsh, consider using enclosures with appropriate ingress protection (IP) ratings.

Tip: Label the device clearly to identify its function and connection points. This makes future troubleshooting and maintenance easier.

Configuring Settings for Optimal Performance

After installation, configure the device settings to match your system’s requirements. Adjust the current rating and trip class based on your motor’s specifications. For example, set the trip current slightly above the motor’s full-load current to avoid unnecessary tripping.

Use the device’s manual to understand its features and settings. Some advanced devices, like electronic overload relays, allow you to fine-tune parameters such as delay times and sensitivity. Take advantage of these features to optimize performance.

Note: Test the settings after configuration to ensure the device responds correctly to overload conditions.

Common Installation Mistakes to Avoid

Many issues arise from improper installation. Avoid connecting the device to incorrect terminals, as this can lead to malfunction. Double-check all wiring connections to ensure they are secure and follow the manufacturer’s wiring diagram.

Do not skip grounding the device. Proper grounding prevents electrical hazards and ensures safe operation. Also, avoid over-tightening screws during mounting, as this can damage the device or its enclosure.

Reminder: Always power off the system before installation or adjustments to prevent accidents.

Maintenance and Troubleshooting Tips

Routine Inspection and Testing

Regular inspections keep your overload protection devices in top condition. Check for visible signs of wear, such as discoloration, loose connections, or physical damage. Inspect the wiring to ensure it remains secure and free from corrosion.

Perform functional tests periodically to confirm the device trips correctly under overload conditions. Use a testing kit or follow the manufacturer’s recommended procedures. For electronic relays, review diagnostic data to identify potential issues early.

Tip: Schedule inspections every three to six months to catch problems before they escalate.

Identifying and Resolving Common Issues

Overload protection devices can sometimes trip unnecessarily or fail to activate when needed. If you notice frequent tripping, verify that the settings match your system’s requirements. Incorrect current ratings or trip classes often cause this issue.

For devices that fail to trip, check for faulty wiring, damaged components, or environmental factors like excessive heat. Clean the device and surrounding area to remove dust or debris that might interfere with its operation.

Reminder: Always disconnect power before troubleshooting to ensure your safety.

When to Replace or Upgrade the Device

Replace your overload protection device if it shows signs of aging, such as cracks, rust, or inconsistent performance. Devices that trip too often or fail to reset may no longer function reliably.

Consider upgrading to a more advanced device if your system’s requirements have changed. For example, electronic relays with remote monitoring capabilities can improve efficiency in modern setups.

Note: Refer to the manufacturer’s lifespan guidelines to determine when replacement is necessary.

Choosing the right overload protection device ensures your equipment operates safely and efficiently. Follow the steps outlined in this guide to make informed decisions and avoid costly mistakes.

Tip: Consult experts or refer to manufacturer guidelines for tailored advice. Proper selection and maintenance protect your investment and enhance system performance.

FAQ

What is the difference between a fuse and a circuit breaker?

A fuse melts to interrupt the circuit and requires replacement. A circuit breaker trips and can be reset for reuse.

How often should you inspect overload protection devices?

Inspect devices every three to six months. Regular checks ensure proper functionality and prevent unexpected failures.

Can you use one device for all applications?

No, each application has unique requirements. Choose a device based on motor specifications, environmental conditions, and compliance standards.

Tip: Always consult the manufacturer’s manual for specific guidance on device selection and maintenance.

Post time: Feb-01-2025